Slic3r is a free 3D printing software for Windows. This software helps you print an input 3D.

Cura is an open source software which makes it compatible with every 3D printer. Besides the fact that Cura is open source, it’s a free software. Everyone is able to use the Cura as the software is pretty basic and easy to use. If needed, there are plugins to expand the software with some extra options.

Builder Premium

Would you like to use Cura with your Builder Premium Small, Medium or Large? Please downloadCura 3.2 (64 bit). The Builder Premium series are integrated in Cura.

Builder Original

Would you like to use Cura with your Builder Original. Please follow the following steps:

Simplify 3D is slicing software which goes deeper into 3D printing than other slicing software. With Simplify 3D, you can optimize many settings to increase your print quality. If you would like to use Simplify 3D you need to purchase a license for the software on www.simplify3D.com.

Pdfpenpro 10 2 45. Would you like to use Simplify 3D along with your Builder Premium? Please download the FFF profile here and upload this in Simplify 3D. The FFF profile provides you with all the settings you need when printing dual objects.

Extreme profiles:

If you have problem with getting the right result, the Simplify3D troubleshooting guide can help you.

Would you like to keep your Builder Premium up to date? Download the latest software update here and follow the 9 steps to install the software correctly.

When connecting the Builder 3D printer to the PC. Windows requires a driver. Only for the Builder and Big Builder Dual-Feed.

● Install the Cura software

Click Cura .exe file, pop-up installation window, continue to click next step to complete the installation.

● Machine settings

For offline printing, do not need to connect to computer, easy to operate with SD card. After install Cura software,Select 'print all the once' from the 'Tools'.

Object operation

Click right mouse function

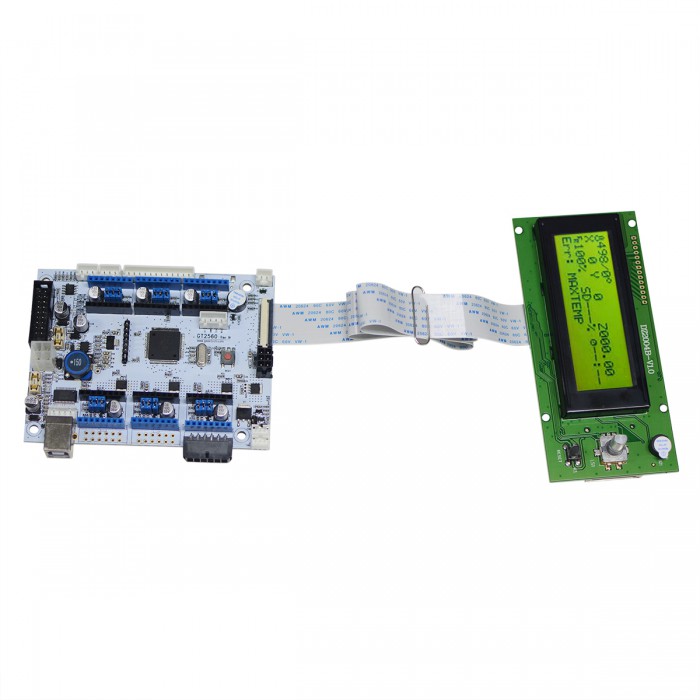

The name of 'filename. gcode' file must be in English or number, do not name it into Chinese characters or others. Save the file to the SD card, then insert it into the card slot and turn on the power. Select 'print from SD' in the main menu from LCD Control Screen, then select the 'filename. gcode' file you just saved and confirm it and begin to print.

Open Cura software,you can modify all of the printing parameters on the display screen.

Select 'Switch to full settings'.

Layer height: 0.1 - 0.4mm available. 0.1mm high precision, but long printing time, 0.4mm low precision, but printing time is too short, in general select 0.2mm.

Shell thickness: 0.4mm is very thin, in general select 1.2mm, that will increase the printing time. 2004 jeep grand cherokee driver door wiring diagram.

Enable retraction: To prevent the wire from leaking when printing quickly, otherwise it will affect the appearance.

Bottom / Top thickness: In order to make the top layer print more perfect and flat bottom layer.

Fill density: If the intensity is not high, select 20%. If the intensity is high, increase it and the printing time also will increase.

Print speed: Generally set 30-100, he print speed is higher and the precision is lower.

Printing temperature: Depends on the filament, generally select 190 - 210 degrees. Etrecheck pro 6 2 2 x 4.

Support type: Include a half-support and full support. In general the model with suspended structure needs to set support, but a surface will be rough after removing support.

Platform adhesion type: 'None' means do not set any support, 'Brim' increases the bottom area. 'Raft' base makes the model more adherent. To make the model better adhere to the base, add a base or edge. But best to increase a base and an edge relative to the small bottom area.

Diameter: 1.75mm

Flow: 100%

Nozzle size: 0.4mm. How to put windows on macbook pro.

Retraction Speed: The speed of retraction when printing.

Retraction distance: The length of material retraction, generally select 4.5 - 8mm.

Initial layer thickness: The first layer thickness of printing. Select default option.

Initial layer line width: 100% will be thicker and denser, Select default option.

Cut off object bottom: The length of cutting off the bottom of model.

Dual extrusion overlap: 0.15mm. Select default option.

Diskcatalogmaker 7 9 0 cm. Travel speed: The moving speed when nozzle does not extrude filament.

Bottom layer speed: The speed of printing the first layer. Setting a slower speed to make object better attached to base plate.

Infill speed, Top / bottom speed, Outer shell speed, Inner Shell speed: Select default option.

Minimal layer time: Select default option.

Enable cooling fan: To cool the temperature of nozzle.

| You may also want to read: |

| How to debug 3D printer’s heating platform |

| How to operate Alfawise U20 3D printer screen |

| How to stop 3D prints from warping |